Choke manifolds may sound like a tough name, but they’re crucial to the oil wells to keep them safe and out of trouble. This specific set of tools is used in the oil and gas industry to direct how fluids are moving through the well. They aid in regulating the pressure in the well that can cause blowouts and other dangerous outcomes.

Choke manifolds are crucial to controlling oil wells. When people drill for oil it is crucial to control the pressure within the well. This prevents a sudden jump in pressure that would lead to a blowout. Choke manifolds aid in regulating the flow of liquids in the well and maintaining that everything functions smoothly and safely.

Choke manifolds are designed to regulate the flow of fluids on the well by varying the size of the choke valve. This valve can be either opened or closed to determine how much fluid the manifold will allow to pass. By manipulating the choke valve, workers can manage the pressure within the well and halt dangerous surges of pressure that could lead to a blowout.

Various types of choke manifolds have been used in the oil and gas industry. Each kind has unique characteristics of its own. Some are built for high-pressure environments and some are better suited for low-pressure ones. Workers should select the appropriate type of choke manifold for the well that they are working with to ensure safety and efficiency.

Choke Manifolds CKH-2.0 8.1Release of PressureSystemWorking withtemperatures or hazardous materials Do not try to releasesystem pressure through the choke manifold Valves where system pressure cannot bereleased via the wellhead and when thefluid doesn't exhibit a dangeroustemperature Do not attempt to releasemannifold system pressure by openingany valves Do not open valve on manifold whenpressure can't be released at the wellhead and/or fluid temperature is hazardous CKH-2.0 9.1Working on the Manifold1. 2.… 3., CKH-2.0 9.2Working on ManifoldSituationalWear eye protection, helmet,protective clothing and earplugsDon't work in proximity with lines and components under pressureCKH-2.0 9.3General Safety: (). 、、 、、 Med Remove name plate, secure plug,minimize paint and guano while workingon the manifold CKH-2.0 9.4Working on Manifold возможностей Source: http://www.doc88.com/p-2352272417622.html

Choke manifold safety is stolidly relevanted in(OPRC). Workers are always going to need to follow the proper steps and rules, so they are using equipment safely and properly. It is also the fact that choke manifolds should be regularly checked and maintained to prevent hazards. Workers can help keep themselves and their colleagues safe on the job by observing safety regulations and paying close attention when using choke manifolds.

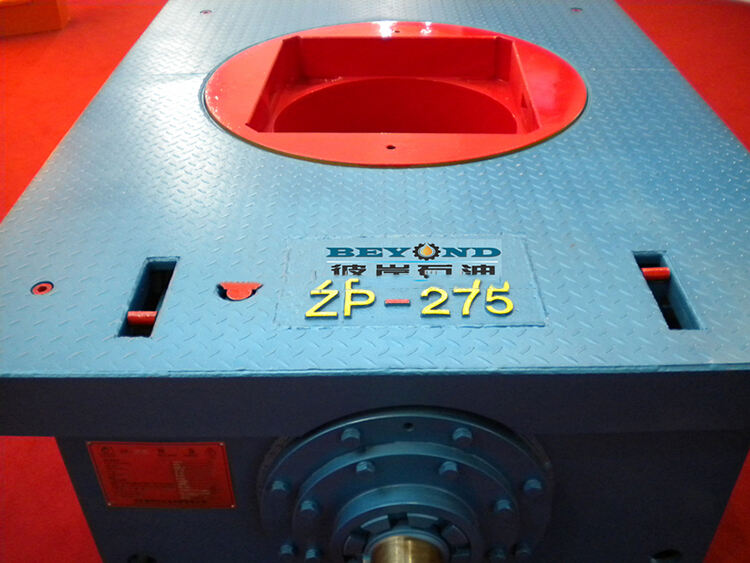

China is the sole country to provide all drilling equipment. We are able to provide customers with one-stop solutions for all kinds of drilling equipments. In particular, for after-sales maintenance of rigs customers may need to purchase from a variety of companies to get the entire list of equipment and parts for the maintenance of the rig. This can cause a lot of headaches for the customer. All these manufacturers are scattered throughout China, and China is a large country. Many of them do not have a foreign-language speaker to communicate in detail for the request from the client and to handle the complex export procedures. It's a daunting task for these companies' procurement departments. But BEYOND, with 15 years experience in this area, can easily choose the choke manifold based on the desired price and delivery schedule as well as other requirements which are communicated in full (either in Russian or English). We assist our clients to manage and provide all of the goods with one-stop purchase.

At BEYOND we are not obliged to any single factory. For any product request on behalf of the customer, we can choose to work with any factory based on the precondition that the following are met: 1)) its product will match the technical specifications provided by our client; 2) it has complete certifications (like API, ISO, EAC for example) that our client requires; 3) the time of delivery can satisfy the requirements of the client's end; 4) Beyond has previously worked with this particular factory before and had positive experiences with them, it indicates that its reliability (either in terms of credit or quality) was proven; 5) This factory is actively involved in technical assistance in the before-sale phase 6.) for new suppliers, BEYOND will make investigation and inspect the factory by choke manifold 7.) this factory has good standing in the business. BEYOND can accomplish this, however the factory is typically only allowed to sell its own products regardless of whether they're excellent or not or if their lead times are slow or fast. BEYOND is able to choose the best supplier for each customer based on the particular requirements and needs of each customer.

BEYOND is not the only supplier but the majority our cooperating companies offer us a solid technical assistance. For BEYOND we supply to over 100 clients from over 50 different countries. So, for every factory, typically we are not their sole customer, but instead we are buying from them for different clients. When it comes to foreign buyers, for a few of their products, perhaps they make a couple of orders for the factory and not more. The factory might not care about whether the client is satisfied or not. However, it's a different situation for BEYOND. We select factories that have a reputation for long-term cooperation not a one-time deal. And for orders from different international customers, we could purchase from the same factory. This factory BEYOND is their most choke manifold client, so they be more attentive to us. No matter if it is for after-sales service or pre-sale they will offer us superior assistance. We will provide an engineer from the factory and an associate from BEYOND for our after-service team.

It's a pity, but it happen that many of our clients have had negative experiences working with a few of the China suppliers. It's not realistic for a foreign client to visit China to examine every factory prior to deciding to cooperate with the company. It's not enough just to go to the factory and inspect it. It is not possible to be certain they are able to comprehend the process completely. This is why disputes are common in transactions between foreign buyers as well as China suppliers. Arbitration or litigation are not the best alternatives to resolve choke manifold. It is challenging for the customer to confirm the authenticity of each factory, but it is easy to verify BEYOND. Just come and have a conversation with us face-to-face, and we will show you all our company profiles and supplying the evaluation and records of our previous customers. After verifying BEYOND as reliable and trustworthy, the rest of the company will be able to respond on BEYOND.