Oilfield pipes are long metal tubes that are crucial to us. They are used to help extract oil and natural gas from deep underground. These resource what we need to keep home-school and business going. These pipes make it really hard to run this energy that is always flowing.

Oilfield pipes, after all, are not mere tubes that allow access between the serene interior depths of Earth and its noisy surface. And there’s plenty of science and engineering that goes into building these pipes and ensuring they work. A lot of different parts come together to help extract the oil and gas in a way that is both efficient and safe.

Drilling this process is one of the main steps. Drilling for oil and gas involves using big machines to bore deep into the Earth’s crust to reach levels where those materials become trapped. This drilling can go very deep, even multiple miles below the surface! Once drilling is complete, oil and gas is brought to the surface and flows through a complex series of pipes, pumps and valves. These pipes lead to something called refineries. Refineries are where the oil and gas get converted into the fuels we use every day, including gasoline for our cars and heating oil for our homes.

Because oil and gas companies need to transport the fuel safely and efficiently, oilfield equipment servicess play a critical role in their operations. Without these pipes, companies would have a hard time accessing energy resources necessary to generate electricity for everyone.

High-Quality Oilfield Pipe Protecting Environment If they leak or spill, oil and gas can be very dangerous. Durable and dependable pipes help stop accidents and spills before they even happen. They are built to withstand the pressure of the oil and gas flowing through them. This ensures the safety of the workforce — and makes sure not to harm the environment in the process.

The most often used material for oilfield pipes is steel. It is quite robust and can hold up to mass pressure, thus making it a prime candidate for penetrating deep. It is also pliable enough to support the weight of the oil and gas. Aluminum is also a used, especially in regions where keeping the pipes light is critical. Smaller jobs that do not require much pressure sometimes utilize plastic pipes.

BeyondPetro goes about that in part with next-generation materials and engineering approaches. They manufacture high-strength pipes designed to endure extreme pressures and high temperatures. These pipes are more lightweight and rugged than those of the previous structure, leading to lesser costs in production and transportation as well.

It's a pity, but it happens that many of our clients have had negative experience working with certain China suppliers. It's not realistic for a client from outside the country to travel to China to inspect each factory prior to beginning collaborate with the company. It's not enough just to go into the factory and examine it. They aren't certain that they can comprehend the facility completely. So, it is not uncommon for disputes to arise when dealings are made between foreign buyers as well as China suppliers. Arbitration or litigation aren't the ideal alternatives for international disputes. It is challenging for the client to check each factories but it is simple to oilfield pipe BEYOND only. You can simply come to us for the chance to talk face to face and we'll give you a list of our company profiles as well as providing documents and evaluation letters from our previous customers. After verifying BEYOND as reliable The rest of us will be able to respond on BEYOND.

BEYOND oilfield pipe be just one supplier however, the majority of our cooperating companies offer us solid technical assistance. For BEYOND we are providing to more than 100 clients from over 50 countries. This means that for each factory, usually we are not their sole client, however we are buying from them for a variety of clients. However, for foreign buyers for a portion of the goods, they only make a couple of orders to the factory, and not more. The factory may not care much whether this client is satisfied or not. But it is a different circumstance for BEYOND. We select factories that have a reputation to work with for a long time and not just a once-off deal. We can choose the same factory to complete orders for different customers. For this factory, BEYOND is their main client, so they take more care of us. They will help us in a professional way no matter for pre-sale or after-sale services. We will send an engineer from the factory, and an associate from BEYOND for our after-service team.

For BEYOND, we're not bound to any one factory. We can work with any factory to produce any product requested by the customer, provided the following conditions are met: 1.) the product has the ability to meet the technical specifications of our client 2) the factory is equipped with all the required certifications by the customer (like API ISO EAC etc) 3.) the delivery time meets the client's expectations, and) we have worked with the factory before and had good experiences, which means their reliability (either in oilfield pipe or in product quality) is proven. 5) BEYOND has conducted an examination and also inspected and certified the quality of the product. BEYOND is able to do this, however the factory is typically only permitted to sell its own products, regardless of whether they are good or poor quality, or whether their lead times are slow or fast. BEYOND can select the best vendor for each client based on the particular requirements and needs of each customer.

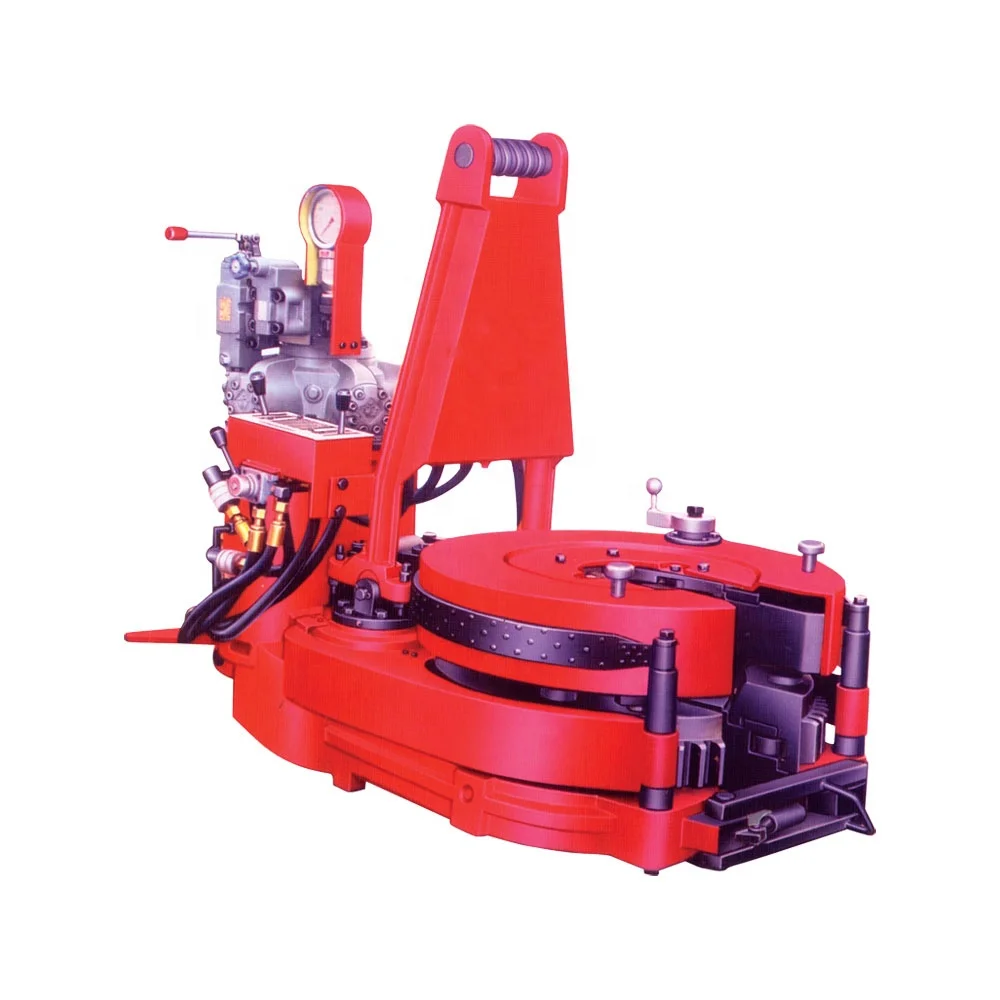

China is the only nation that can provide all drilling equipment. We can offer clients a one-stop solution for different drilling equipments. The client must purchase from multiple companies to get the complete list of components and equipment to ensure the maintenance after sale of the drilling rig. This can be a major burden for the client. All these manufacturers are scattered throughout China and China is a large country. Many of them do not have foreign langauge speakers to be able to talk in depth to the customer and also to manage the complex export procedures. It is a challenging job for the procurement department of these drilling companies. But BEYOND having 15 years experience in this field, is able to easily choose the best supplier on the basis of the price and delivery schedule and other conditions that are based on complete communication (either in oilfield pipe or English). We assist our clients to manage and provide all of the goods by one-stop procurement.