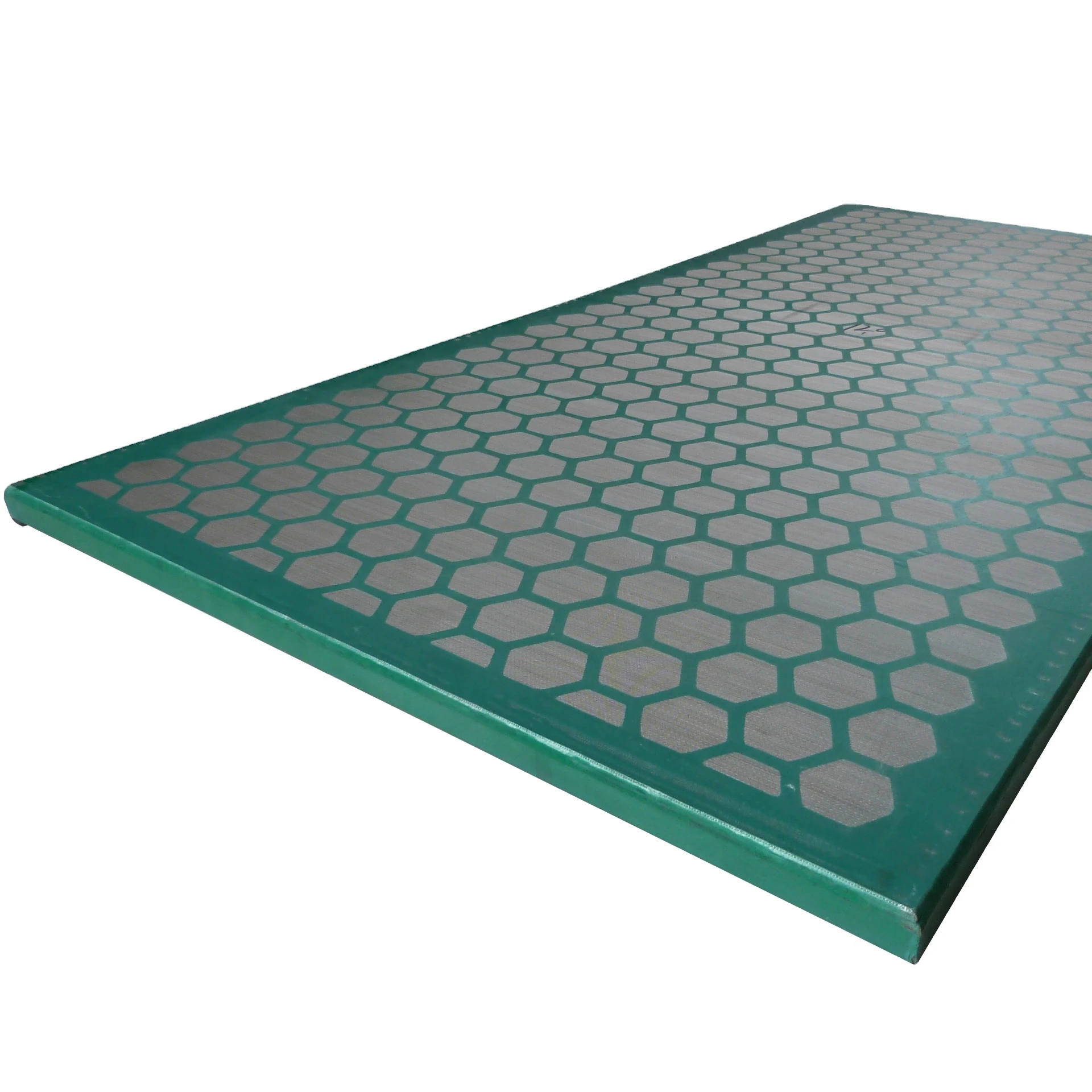

Detachable drill floor componens Shale shakers are critical devices in oil drilling. They help to remove solids from drilling fluids. This allows the fluids to be reused and the solids to be disposed of properly. Understanding how shale shaker screen work and the types of shakers available can help optimize efficiency on the jobsite.

Shale shakers separate solids from drilling fluids. This matters because the drilling fluids have to be clean in order to work well. The shaker comes with a vibrating screen that sifts the solids in the slurry from the fluids. That way, you can keep recycling the fluids and dispose of the solids correctly.

Shale shakers are available in several types, none of which work on that principle. Some blowout prevention are better at separating solids than others, which means that they can keep the drilling fluid cleaner. Meanwhile, We need to choose the reasonable shale shaker for drilling to make drilling save cost.

It is quite vital to maintain the shale shaker appropriately so that it works well. Cleaning them frequently and looking for issues will help prevent problems such as blockages and broken motors. Through properly maintaining shale shakers, drilling can be perfect with minimal idle time and less cost.

The drilling process can be even better with new technology, like high–performance screens and automatic cleaning systems on shale shakers. The new tools can make shale shakers more efficient, so they can move faster and need people to help less. With new shaker technology, drilling companies can do better and make more money.”

Shale shakers contribute to environmental safety in the oil and gas industry. They also stop pollution in natural habitats and groundwater by extracting solids from drilling fluids. Maintaining shale shakers and taking advantage of new technology can make oil drilling better for the environment, making it more sustainable.