A tri cone Bit is a very powerful tool used for drilling. This instrument forms a hole in the outer crust of the Earth As its name reasons the only difference is that this bit has three cones each of them having sharp teeth at their bottom part and you know how it looks like with all we mentioned above A tri cone_photo or img. The resulting cones rotate fast and drill deep into the soil to create larger holes.

Tri cone bits are commonly used in the drilling process for oil and gas. This is for a million reasons, and these bits are one of the best ways to engage so many good things. For example, they are built with very strong materials. In other words, they are strong and stable enough to withstand the force of drilling deep into the ground while not being worn out or fractured easily.

Next, tricone bits are capable of drilling tangible in various rock type. They can have different teeth design like tungsten carbide, diamond or studded types and they are to work on various rocks such as Sandstone, Limestone, Shale etc. For this reason, bit pdcs are a go-to option for various hole drilling applications that need to be performed in different locations.

Finally, tricone drill bits are cost-effective too. The reason that these metal roofs are so prevalent is that they also last an incredibly long time and do not require much maintenance or repairs during their life. This both in terms of time and money for drilling companies, which is why many use them three cone bits to their boring activities.

Tri cone bits are not exclusively the province of oil and gas; they are also very critical in mining. These bits are used in mining operations to bore holes into the ground for production of valuable minerals, resources. Different tri cone bit is usually used in specific minerals and rocks that are found within the area to be excavated.

The best way is to start with the kind of rock formation. The tri cone bit teeth differ in size and shape depending on the type of rocks to be drilled. Shale rock formations, for instance, often call for bitted with a more aggressive tooth pattern than the bits companies might use in softer limestone formation.

A next approach is to look at the specific mineral you are mining. Hardness: some minerals are harder than others requiring tougher and stronger bits. This is because when drilling for diamonds, you will need to make use of the very best bits around (bits which are strong enough with an especially aggressive tooth pattern so as to be able cope and cut its way properly through a tough material such as that).

At BEYOND we are not obliged to any single factory. For any product request on behalf of the customer, we can choose to work with any factory based on the precondition that the following are met: 1)) its product will match the technical specifications provided by our client; 2) it has complete certifications (like API, ISO, EAC for example) that our client requires; 3) the time of delivery can satisfy the requirements of the client's end; 4) Beyond has previously worked with this particular factory before and had positive experiences with them, it indicates that its reliability (either in terms of credit or quality) was proven; 5) This factory is actively involved in technical assistance in the before-sale phase 6.) for new suppliers, BEYOND will make investigation and inspect the factory by tri cone bit 7.) this factory has good standing in the business. BEYOND can accomplish this, however the factory is typically only allowed to sell its own products regardless of whether they're excellent or not or if their lead times are slow or fast. BEYOND is able to choose the best supplier for each customer based on the particular requirements and needs of each customer.

A lot of our clients have had a bad experience dealing with China suppliers. It's not realistic for a foreign client to visit China to examine each factory prior to beginning cooperate with the company. Even if they come to the factory to inspect it but that doesn't mean they can have full and clear understanding of the products and can provide tri cone bit according to the contract. Therefore, disputes often happen in the deals between foreign buyers as well as China suppliers. The courts or arbitration aren't the most suitable alternatives to resolve international disputes. It can be difficult for the client to verify every factory but it's easy to check BEYOND. Come and talk to us face-to-face. We'll provide you with our company's profile information, as well as evaluation letters and other records from our other customers. Once BEYOND has been verified as reliable then the rest of the world will take notice of BEYOND.

BEYOND might be just one supplier, but the majority of our suppliers offer us a solid technical assistance. BEYOND provides to more than 100 clients spread across 50 countries. We're not a customer of every factory. We instead purchase from them on behalf of different clients. However, for foreign buyers, for certain of their products, perhaps they just make a couple of orders for the factory but not much more. It doesn't matter to the manufacturer if this customer is happy or not. But that is not the case for BEYOND. We'll pick trustworthy factories for long-term collaboration, not only for one time deal. When we receive orders from various foreign clients, we may purchase from the same factory. This factory will be able to give us more consideration because BEYOND is a regular client. It doesn't matter if it's an tri cone bit or pre-sale they will provide us with excellent assistance. Our mode for after-sale service is that we will dispatch engineer from factory and coordinators from BEYOND as an after-service team to provide best support to our client.

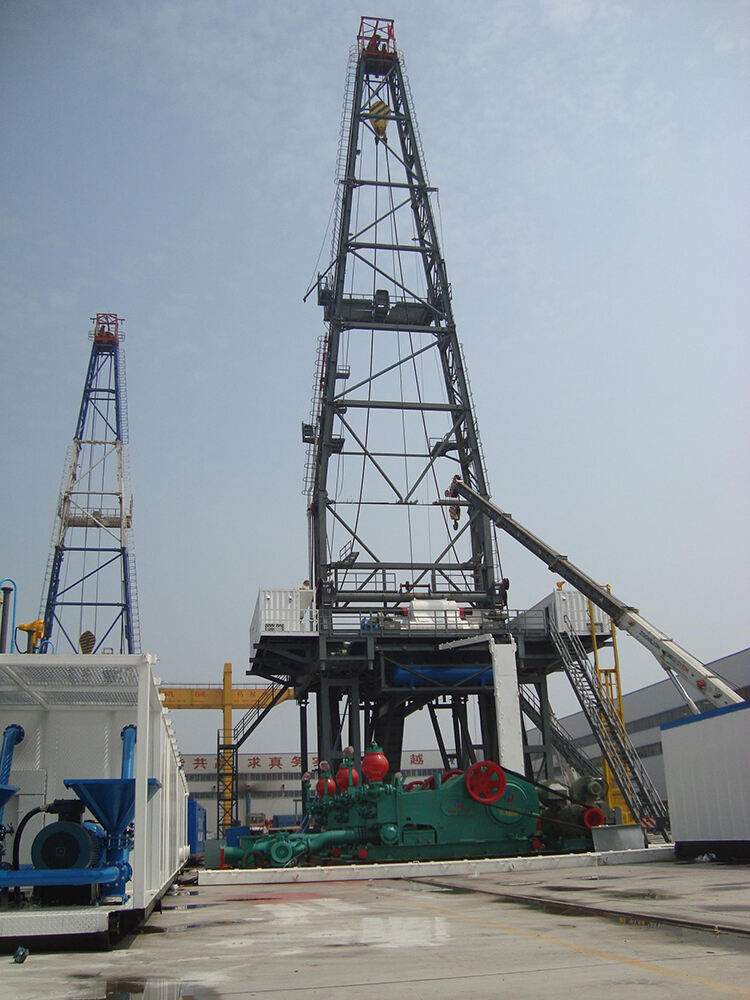

China is the only nation that can provide all drilling equipment. We can offer clients a one-stop solution for different drilling equipments. The client must purchase from multiple companies to get the complete list of components and equipment to ensure the maintenance after sale of the drilling rig. This can be a major burden for the client. All these manufacturers are scattered throughout China and China is a large country. Many of them do not have foreign langauge speakers to be able to talk in depth to the customer and also to manage the complex export procedures. It is a challenging job for the procurement department of these drilling companies. But BEYOND having 15 years experience in this field, is able to easily choose the best supplier on the basis of the price and delivery schedule and other conditions that are based on complete communication (either in tri cone bit or English). We assist our clients to manage and provide all of the goods by one-stop procurement.