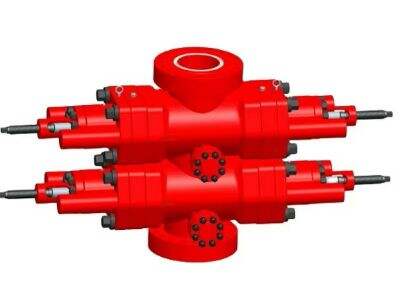

Blowout Preventers Are Known To The Industry Simply As Bops

Fundamental components of the oil and gas industry, particularly BeyondPetro. BOPs are part of what keeps wells safe by controlling unplanned surges of underground fluids. Maintaining these devices isn't just a mundane task — it's a necessary process that keeps drilling operations safe and efficient. But the regularity of BOP servicing can differ and is a key factor in well control preparedness.

The Value of BOP Maintenance on Well Control Readiness

It is important to keep BOPs in working condition because they help to prevent blowouts, uncontrolled releases of crude oil or natural gas from a well. They are lethal and fuel colossal environmental disasters and loss of life. When annular bop are regularly checked and serviced, they will perform as designed in key moments, helping to maintain the well and workers’ safety. At BeyondPetro, we maintain this upkeep for our jobs to work efficiently and safely.

Factors and Analysis of the Frequency of BOP Maintenance and Its Impacts on Well Control

There are various factors that need to be considered when determining the frequency of BOP maintenance. Among them are the age of the equipment, the environment that the equipment operates in and how many times the BOP gets run. Older BOPs may require more frequent inspections to ensure they are working properly. Additionally, BOPs used in rugged environments with wide-ranging temperatures and environments that are corrosive to equipment might need maintenance performed more often. By overlooking these factors, you may put well control at risk and lives or the environment in danger.

The Importance of Regular Preventive Maintenance of BOP in the Well Control Process

The maintenance routine of a BOPs includes regular inspection, repairs and the replacement of parts that are damaged. This maintenance will help to ensure the bop drilling rig deliver as designed in the event of an emergency. Above all else, continual attention benefits BeyondPetro in terms of minimizing downtime and maximizing drilling efficiency with well-maintained rigs that minimize the potential for unplanned repairs and non-productive time.

Optimized Cumulative BOP Maintenance Intervals for Depth-Variable Well Control Preparedness

Getting the timing on maintenance right is crucial. If we do too much maintenance, it becomes expensive and takes a lot of time and if there is very little maintenance, the equipment may fail. BeyondPetro’s approach aims to find a middle ground, obedient to manufacturers’ advice but varying maintenance schedules according to operational data. Governed by this tailor-made approach, we believe that it is possible to continue to ensure high safety standards, while making both savings and efficiency gains.

Common Sense Of Well Control & Bop Maintenance

Operational well control excellence is not only about avoiding mishap but also being on point to effectively deal with them if they happen. At BeyondPetro, we do this by proper training of its people, daily drills and constant vigil over its ram bop upkeep STATUS. Through this broad approach to readiness we are able to respond to well control events efficiently and continue to build on our reputation for both performance and safety in everything we do.

Through continuous BOP management, BeyondPetro is not only securing doing business in a safe manner but also improving our operating efficiency and level of preparedness in the event of any well control challenges. And that dedication to excellence is what differentiates us in the oil and gas business.

Table of Contents

- Blowout Preventers Are Known To The Industry Simply As Bops

- The Value of BOP Maintenance on Well Control Readiness

- Factors and Analysis of the Frequency of BOP Maintenance and Its Impacts on Well Control

- The Importance of Regular Preventive Maintenance of BOP in the Well Control Process

- Optimized Cumulative BOP Maintenance Intervals for Depth-Variable Well Control Preparedness

- Common Sense Of Well Control & Bop Maintenance

EN

EN

AR

AR

FR

FR

HI

HI

IT

IT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

UK

UK

SQ

SQ

TR

TR

FA

FA

MS

MS

AZ

AZ

KA

KA

MN

MN

KK

KK

UZ

UZ

KY

KY