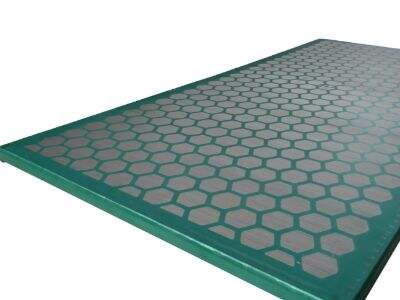

The shaker screens that work in saltwater are particularly susceptible to this type of corrosion. The metal in the screens can become rusty and erode due to saltwater, distorting displays over time. This can cause the screens to be less effective at straining out debris and other material when oil is drilled. But there are steps you can take to avoid the corrosion and to make sure shale shaker screen last a while.

What Is Corrosion?

Corrosion When metal comes in contact with saltwater or other destructive substances. Saltwater does a really good job of corroding, since it is, after all, all salt, and salt can eat away at metals. If shale shaker screener are in salt water for too long, there may be the risk of rust and the screen damaged. This can create holes and other damage that prevents the screens from working as effectively at separating materials as they are during drilling.

Why Maintenance Is Important

It’s important to maintain the shale shaker screens to prevent corrosion from salt water. Frequent cleaning and inspection can remove any salt or dirt that might lead to rust. Equally critical is to keep the screens well lubricated, and to repair damage as soon as you spot it. By maintaining the screens, they can last longer and prevent serious corrosion issues.

Novel Materials for Corrosion Mitigation

Materials have been processed recently to aid in the prevention of saltwater corrosion of shale shaker screens. Some companies are now employing special coatings and metals that are more resistant to saltwater. These new materials can keep shale shaker screens safe and can allow them to work effectively for a longer amount of time. Companies can reduce the risk of corrosion and ensure their equipment continues to work properly by selecting the right materials.

Shale Shaker Screen Maintenance and Best Practices

However, a number of best practices can be followed that will help extend the life of shale shaker screens in saltwater. Regular cleansing and upkeep are crucial. It is also necessary to keep flies greased and damage repaired. It’s a good idea to monitor the screens closely for signs of corrosion and replace whenever necessary. With these methods companies can minimize the appearance of corrosion and longevity of their shale shaker screens.

Difficulties in Protecting Corrosion

It’s tough to fight corrosion on shale shaker screens in saltwater, but it’s possible. Higher cost for these materials, and conscientious use of them, combined with good maintenance and the need to keep an eye out for corrosion allow one to adequately manage the challenges presented by saltwater corrosion. With the correct plan, shale shaker screens can be well kept and can ensure the best shape for performing during the oil drilling.

EN

EN

AR

AR

FR

FR

HI

HI

IT

IT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

UK

UK

SQ

SQ

TR

TR

FA

FA

MS

MS

AZ

AZ

KA

KA

MN

MN

KK

KK

UZ

UZ

KY

KY